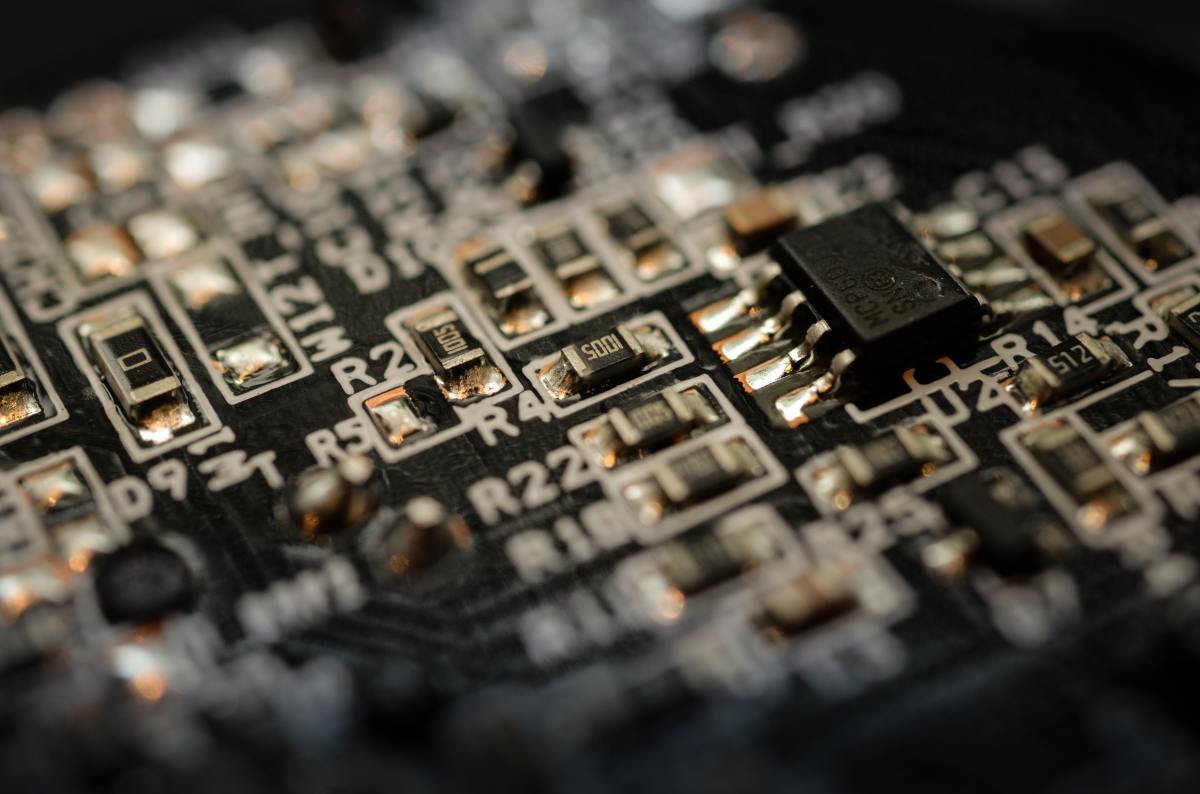

Photo by Skitterphoto on Pexels Circuit boards can be refitted and returned to the original specifications for way less than purchasing a replacement. With the right skill, you can repair all PCB problems. But, sometimes, the PCB board can be damaged beyond any realistic repair. Simple component replacement and soldering might be appropriate for less complicated PCB repairs. But, repairing complete circuit board assemblies may be difficult and requires a systematic approach to detect and fix the issues quickly. Continue reading this post to understand how to repair a damaged printed circuit board.

Reasons Why PCBs Fail

Before you repair any board, you need to inspect and know the reason for its failure. You cannot successfully fix an issue when you don’t know the cause, can you?Knowing some of the common causes of circuit board failure is greatly beneficial. You will at least know where to start in case your electronic device fails. For that reason, let’s go through the common PCB problems:

Physical Damage

Impact damage due to dropping or rough handling of PCB can present in several ways. From cracked components and broken BGA pads to damaged golf fingers, it can be tough to identify PCB repair problems due to physical damage.

Component Failure

Other than physical damage, defective PCB components are the next most common reason why printed circuit boards fail. You can be certain that the problem is component related when there is no impact damage.

Gold Finger Damage

Gold fingers are elements on your PCB periphery normally exposed to solder splash when wave soldering. The circuit board may not function as desired when the edge contacts are tainted with solder or spoiled.

BGA Pad Damage

BGA pads may get damaged when you remove the component or because of rough handling when cleaning or transporting. Due to this damage, the mounted part might not perform efficiently on the PCB board.

Through-Holes And Vias Damage

Plated thru-holes and vias are vital to the correct multilayer PCB functioning. These through-holes may endure damage from rough handling or incorrect part removal. Consequently, you may need to repair the PCB.

Corrosion

Exposure to water, air and other contaminants may cause metal conductors to form a rust layer. This layer lowers conductivity, diminishing the circuit board efficiency and raising the possibility of short-circuiting. Exposure to chemicals may also result in PCB corrosion.

Broken Traces

Similarly, rough handling or incorrect part removal can spoil PCB traces. These traces cannot conduct signals if spoilt, leading to circuit board malfunction.

Damaged Edges

You can easily damage the edges and corners of your PCB when transporting and handling them. Consequently, there may be delamination and issues with components and circuit board traces near the edge.

Solder Mask Delamination

Mishandling or poor quality can result in partial or complete removal of solder masks. Moreover, mechanical damage or extreme heat may cause partial or total detachment of solder mask material. As a result, this may negatively affect the board’s appearance and lead to serious PCB repair and maintenance problems.

How to Perform PCB Board Repair

PCB board repairs can be very demanding; therefore, you need to possess the relevant knowledge and expertise related to the subject. Some PCB repair problems, such as trace damage, are easy to pinpoint, while others might be more challenging to identify. Accordingly, you must deliberate before carrying out the PCB rework and repair to avoid causing more damage. Let’s look at the essential considerations before you start repairing circuit boards.

Factors to Consider Before Circuit Board Repair

You need to consider these factors when determining whether to repair PCB or not:

Cost of replacing the electronic device Role of the device Cost of a new device or PCB Downtime duration when replacing the circuit board Downtime duration when repairing the board Scope of repair work

PCB Repair Tools

There are exceptionally good tools for repairing printed circuit boards. Here are some important PCB repair tools that you will need:

Ergonomic Workstation

When performing printed circuit board repair, you will require an ESD grounded workstation featuring proper outlets, lighting and comfort. You can bolt frequently used systems to the workstation to enhance efficiency.

Quality Stereo Microscope

Conducting precision PCB repair is not possible without this type of microscope. Avoid video monitors and cameras since they do not offer the clarity provided by a quality stereo microscope.

Soldering Tool

Precision soldering is critical in modern PCB rework and repair process. You need the finest soldering irons that have an ergonomic design. The PCB repair tool should also be greatly controlled and feature a broad collection of small tips.

Component Removal Tools

You require some professional PCB repair kit for harmless, efficient parts removal. Generally, these tools for working on circuit boards employ either infrared heating (focused IR lamps), convective heating (hot gas), or conductive heating (contact).

Preheating Station

In addition to drying/curing oven, it is necessary to have a preheating station. You can use an infrared heater or hotplate-type preheater. Preheating quickens the process of finding PCB problems and solutions and reduces thermal shock because of localized heating within the repair area.

Micro Precision Drilling System

Due to the thorough work involved during circuit board testing and repair process, a light, top-quality, dental-style drilling and grinding tool is necessary. The tool is vital because high speed, accurate depth control and precision are key when making grooves, slots and holes.

Replacement Pads and Circuitries

The replacement circuitries and pads come in a variety of patterns. Mounting the parts entails heat-bonding them to the printed circuit board surface.

Gold Contact Plating Mechanism

Make sure you have an efficient plating system to achieve safe, reliable plating of gold edge contacts. The system must facilitate proper handling of the hazardous chemicals and guarantee a controlled power supply to plating surfaces.

Epoxy Kits and Solder Mask

You need high strength, elevated temperature epoxies in your circuit board soldering kit. Two-part epoxy is the best choice since it gives high thermal resistance, strength, and longevity not provided by quick-setting and one-part epoxies. Similarly, a PCB solder mask is important for restoring the cosmetic circuit board appearance. If possible, use a drying oven to cure the epoxies.

Eyelet Press and Eyelets

Typically, you will need an eyelet press and copper-plated eyelets for repairing PCB through holes.

Repairing Common PCB Problems

The main advantage of printed circuit board repair is that you can always finish the process faster than board replacement. Furthermore, the repair is usually less costly based on the extent of damages. Because of how complicated the process can be, repairing faulty PCBs must be performed by an expert to avoid causing more damage. That said, let’s now look at ways of how troubleshoot printed circuit board common problems.

Physical Damage

Provided the problem is not caused by total PCB failure, you can correct physical damage through PCB remanufacturing procedure. Typically, this entails melting down the defective part or restoring it by disassembly and reassembly. Often, the process requires circuit board redesigning, PCB components resoldering, and reballing of PCB traces.

Component Failure

In most instances, you can spot a broken PCB component by visually inspecting the printed circuit board. Their external shell might appear broken, burnt, or cracked, or the part could be wholly detached from the board. Moreover, several tools are used in repairing PCB that you can use to test the circuit board conductivity. The tools can also help establish if electricity flows to the component or is damaged completely. You may fix PCB component failure through resoldering of the part or by component replacement.

Trace Damage

Provided the printed circuit board does not have exceedingly thin traces, you can pinpoint PCB trace damage by inspecting the pathway. Reballing or resoldering using necessary material is the simplest method of repairing broken PCB trace. Doing this restores the broken circuitry and enables the free flow of electrical signals across the circuit board.

Poor Design

A poor circuit board design will fail continually even after repair. You will know your board is poorly designed if it has many issues after PCB testing and repair. The preferred solution to poor design is replacing the PCB wholly.

Power Failure

Outside noticeable damage to the PCB component, a voltage meter is the best device for checking electrical issues in a circuit board. Typically, replacing components or reseating is the simplest way of solving PCB electrical problems.

Conclusion

You can experience printed circuit board problems, from traces and components failure to physical damage. With comprehensive PCB troubleshooting, you can pinpoint and fix every issue to restore the circuit board to its original specifications. This article is accurate and true to the best of the author’s knowledge. Content is for informational or entertainment purposes only and does not substitute for personal counsel or professional advice in business, financial, legal, or technical matters.